HDPE PP avfall plast flak pelletizing resirkuleringsmaskin

Beskrivelse:

HDPE PP waste plastic flakes pelletizing recycling machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, etc.

After the processing of feeding, heating, melt, cooling, drying, cutting etc., the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, avløpsrør, plastic sheet etc.

vidoe of HDPE PP waste plastic flakes pelletizing recycling machine

Working Flow of HDPE PP waste plastic flakes pelletizing recycling machine:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

Photos of HDPE PP waste plastic flakes pelletizing recycling machine

Mian extruder machine of HDPE PP waste plastic flakes pelletizing recycling machine

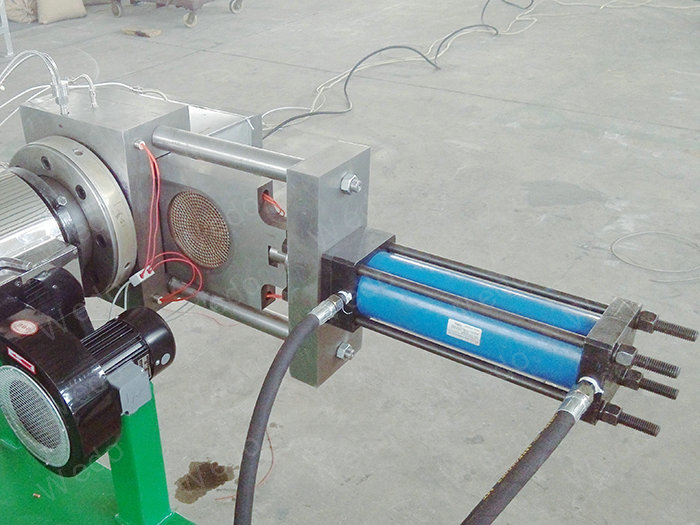

No-stop hydraulic sceen changer of HDPE PP waste plastic flakes pelletizing recycling machine

Second extruder, baby extruder of HDPE PP waste plastic flakes pelletizing recycling machine

hydraulic station of HDPE PP waste plastic flakes pelletizing recycling machine

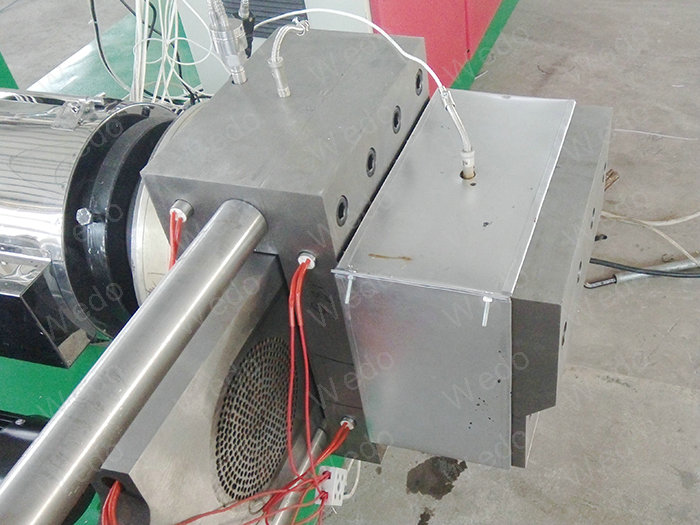

Die head of HDPE PP waste plastic flakes pelletizing recycling machine

Pelletizer cutter of HDPE PP waste plastic flakes pelletizing recycling machine

Final pellets get from HDPE PP waste plastic flakes pelletizing recycling machine

The main parts function in HDPE PP waste plastic flakes pelletizing recycling machine(canbe customizable)

- Screw feeder: the first step of the pelletizing recycling machine, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

- Ekstruder: til plastisering og avgassing, en spesialisert enkeltskrueekstruder brukt for å smelte det forhåndskomprimerte materialet. Plastrester vil godt smelte, plastifisert i første trinns ekstruder, og plasten vil bli ekstrudert av andre trinns ekstruder. Med dobbeltsone vakuumavgassingssystem, flyktige stoffer som lavmolekylær og fuktighet vil bli fjernet effektivitet, spesielt egnet til kraftig trykt film og materiale med noe vanninnhold.

- Non-stop hydraulisk silfilterskifter: dobbelttrinns filtrering, forfiltrering i den første ekstruderen, og finfiltrering i den andre ekstruderen, for å redusere frekvensen av skiftende filtreringssikter. Kravene til filterteknologien avhenger sterkt av kvaliteten på tilførselsmaterialet samt planlagt bruk av granulat.

- Water cooling: made of 304 rustfritt stål, 4 meters length that fill with water, too cooling the melted plastic.

- Cutting pelletizing: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Parameters of HDPE PP waste plastic flakes pelletizing recycling machine:

| KAPASITET (kg/t) |

STRØMFORBRUK (kw) |

VANNFORBRUK | ARBEID | FUKTIGHETSINNHOLD |

| 100-150 | 150 | Hold vannet kjølig | 1-2 | <2 % |

| 250-300 | 200 | Hold vannet kjølig | 1-2 | <2 % |

| 350-400 | 280 | Hold vannet kjølig | 1-2 | <2 % |

| 450-500 | 360 | Hold vannet kjølig | 1-2 | <2 % |

Advantage of HDPE PP waste plastic flakes pelletizing recycling machine:

Svært lav arbeidsbehov.

Stabil løping.

Automatisk konstant temperaturkontroll.

CE-sertifisering, ISO9001 sertifisering, SGS sertifisering

Konfigurasjon basert på klientkrav og materiale, og gi fornuftige forslag.