PA66 GF25 Polyamidin lämpömurtoprofiilinauhan ekstruusiokone

Product Description

Hyödyllisyysmallissa käytetään pääasiassa erityistä ruuvia polyamidi-nailonin valmistukseen 66 ja lasikuitu saa hyvän pehmityksen, ja ekstruusiomuotit/työkalut ekstrudoidaan lämpöä eristäväksi profiiliksi, jota käytetään laajalti ovissa, ikkunat ja verhoseinät alumiinilevyt muottien/työkalujen eri osien läpi.

PA66+GF25 pellets after drying machine into the hopper into the barrel, screw and pellets contact with the rotation of the screw forced to promote the spiral groove die direction. Because the screw barrel gap is small, the granular material is hot body under great pressure in the forward process; the temperature of the electric heating ring body is plasticizing nylon thermosol. Nylon plastic and plastic compression heating hot melt by extrusion molding, after traction, cutting or rolling process and become adiabatic adhesive tape products.

Vidoe of PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

Why use polyamide profile strip bar as thermal barrier function?

1. Because polyamide profile including Polyamide and glass fiber, Its Strength can reach requirement for aluminum profile window, door, curtain and walls.

2. Conductivity of polyamide strip is very low, prohibit hot air or cold air transferred from outside to inside, energy saving product.

“Wear a process” heat insulation material – the current domestic thermal insulation profile is polyamide 66+GF25 (Polyamide66, commonly known as nylon 66+25% glass fiber)

| 1 main materials | PA66+GF |

| 2 density (g/cm3) | 1.3 |

| 3 tensile strength | (N/mm2 = 110) |

| 4 elastic modulus (N/mm2) | 900 |

| 5 thermal conductivity (W/m2.k) | 0.3 |

| 6 hot deformation temperature (℃) | 250 |

Application of polyamide profile:

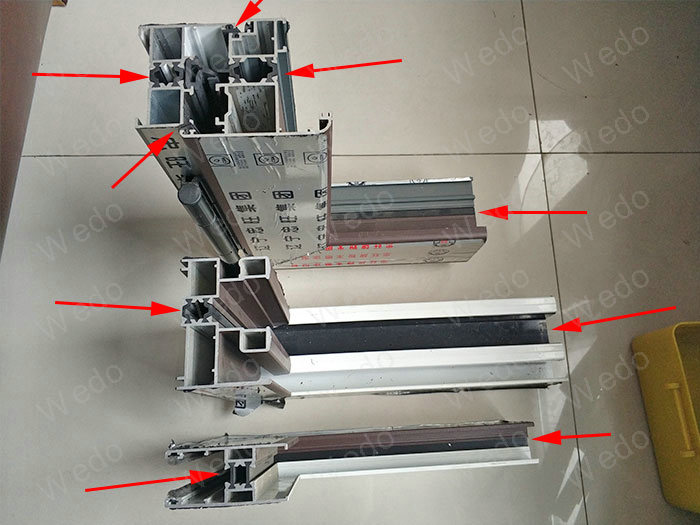

- Used for thermal break aluminum window, door, curtain and walls

- Many customer use thermal break aluminum profile to do big air conditioner to keep heat of cold air, then make use of energy saving

Photos of PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

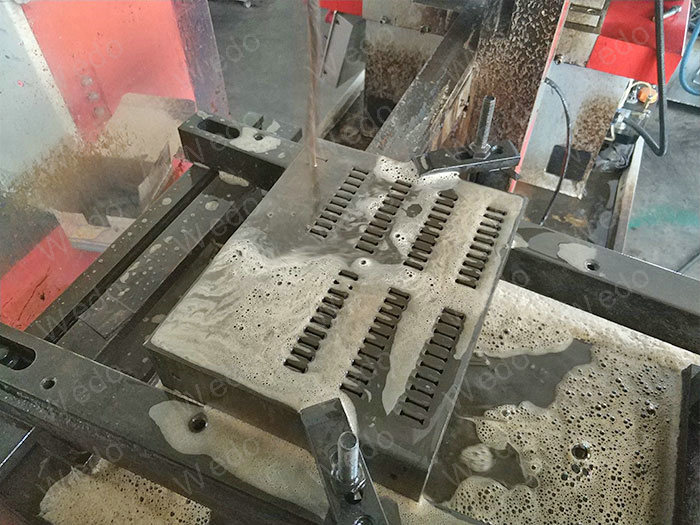

the testing of PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

Good surface get from PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

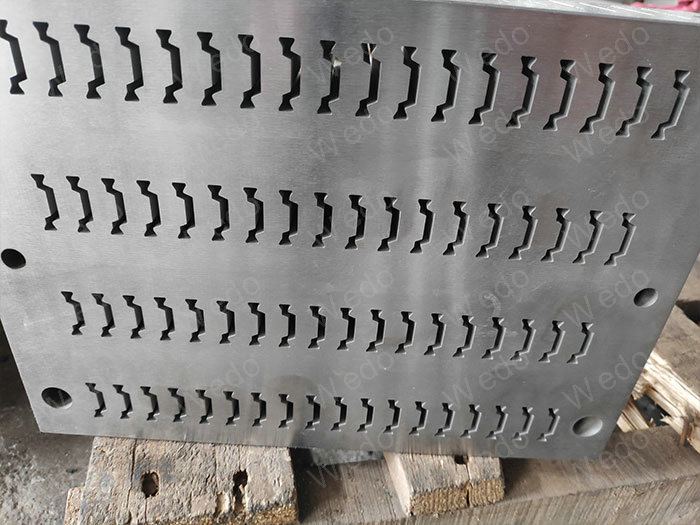

cutting mold for PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

Finish mold of PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

PA thermal breake profile strip bars produced by PA66 GF25 Polyamide thermal break profile bar strip extrusion machine

PA thermal breake profile strip bars produced by PA66 GF25 Polyamide thermal break profile bar strip extrusion machine usage

PA66 GF25 Polyamide thermal break profile bar strip extrusion machine including:

| 1, Raw material loading device(automatic) |

| 2, Raw material drying device |

| 3, Main thermal break strip extruder |

| 4, Polyamide strip moulds / tools |

| 5, Multiple polyamide strip cutting machine |

| 6, Control cabinet |