PP PE återvinningsmaskin för pelletisering av plastfilm

Beskrivning:

PP PE waste plastic film pelletizing recycling machine with international advanced recycling technology and combined with the actual application condition. Denna återvinningsmaskin för plastpellets är design specialiserad för återvinning av den tvättade PE-plastfilmen, såsom PE-plastpåsar, plastförpackningsfilmer, plastpåsar, agricultural film etc.

After PE PP plastic pelletizing machine processing, the final products are plastic pellets/granules, which can be to produce plastic bags, dräneringsrör, plastic board/sheet etc.

Video of PP PE waste plastic film pelletizing recycling machine

The whole PP PE waste plastic film pelletizing recycling machine line includes(anpassningsbar):

Belt conveyor → Compression barrel (agglomerator) → Efficient extruder → Non-stop hydraulic screen filter changer → Water ring cutting → Vibration machine → Dewatering machine → Blower → Storage hopper. Electric control panel

Photos of PP PE waste plastic film pelletizing recycling machine

Belt conveyor of PP PE waste plastic film pelletizing recycling machine

Compress barrel, agglomerator of PP PE waste plastic film pelletizing recycling machine

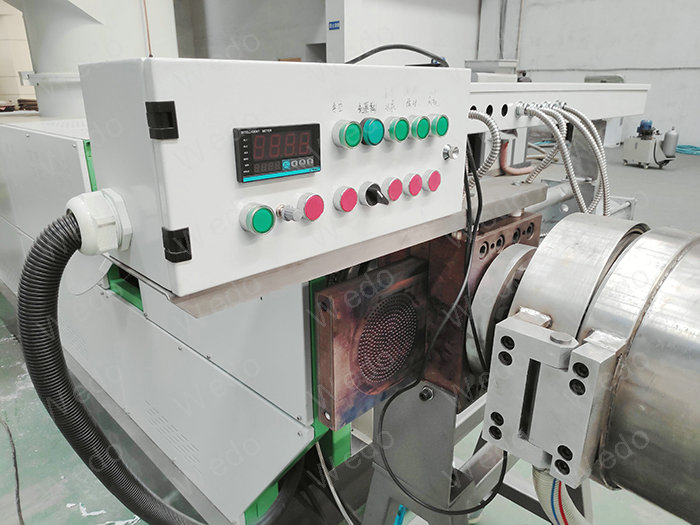

Extruder of PP PE waste plastic film pelletizing recycling machine

Hydraulic filter screen changer of PP PE waste plastic film pelletizing recycling machine

Watering cutting die head of PP PE waste plastic film pelletizing recycling machine

Vibrating machine of PP PE waste plastic film pelletizing recycling machine

The pellets get from PP PE waste plastic film pelletizing recycling machine

Function of the main parts in PP PE waste plastic film pelletizing recycling machine:

- Belt conveyor feeding: as standard design, plastic scraps such as film, bag, filament, raffia conveyed into the compacting barrel through belt conveyor; to process rolls’ scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt and roll hauling off is fully automatic based on compactor’s barrel’ space. Metal detector can combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal into the screw.

- Compression barrel: crushing and compacting the material, the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high-speed rotatory blades will heat the scraps, and let them shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material, which enables a fast and stable feeding from the compactor directly into the extruder.

- Extruder: till plasticering och avgasning, en specialiserad enskruvsextruder som används för att smälta det förkomprimerade materialet. Plastrester kommer att smälta väl, plastad i det första stegets extruder, och plasten kommer att extruderas av andrastegsextrudern. Med dubbelzons vakuumavgasningssystem, flyktiga ämnen såsom lågmolekylära och fukt kommer att avlägsnas effektivitet, speciellt lämplig för tung tryckt film och material med viss vattenhalt.

- Non-stop hydraulisk silfilterväxlare: dubbelstegsfiltrering, förfiltrering i den första extrudern, och finfiltrering i den andra extrudern, för att minska frekvensen av filtreringssilar som ändras. Kraven på filtertekniken beror mycket på kvaliteten på insatsmaterialet samt den planerade användningen av granulat.

- Skärning pelletisering: die-face water ring pelletizing system as the standard granulating method in Wedo system. Self-adjusting pelletizing head for the best granulate quality, and consistently correct blades pressure can ensure long running. Rotate speed of cutting blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with vertical-type centrifugal dewatering present high performance dried pellets.

Parameters of PP PE waste plastic film pelletizing recycling machine:

| KAPACITET (kg/h) |

ENERGIFÖRBRUKNING (kw) |

VATTEN KONSUMPTION | ARBETSKRAFT | FUKTIGHET |

| 100-150 | 150 | Håll vattnet svalt | 1-2 | <2 % |

| 200-300 | 200 | Håll vattnet svalt | 1-2 | <2 % |

| 300-400 | 280 | Håll vattnet svalt | 1-2 | <2 % |

| 450-500 | 350 | Håll vattnet svalt | 1-2 | <2 % |

| 700-800 | 460 | Håll vattnet svalt | 1-2 | <2 % |

Advantage of PP PE waste plastic film pelletizing recycling machine:

Mycket låg arbetskraftsförfrågan.

Stabil löpning.

Automatisk konstant temperaturkontroll.

CE-certifiering, ISO9001 certifiering, SGS-certifiering

Konfiguration baserad på kundens krav och material, och ge rimliga förslag.