HDPE PP廃プラスチックフレークペレタイジングリサイクル機

説明:

HDPE PP waste plastic flakes pelletizing recycling machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, 等.

After the processing of feeding, 暖房, 溶けた, 冷却, 乾燥, カットなど, the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, 排水管, plastic sheet etc.

vidoe of HDPE PP waste plastic flakes pelletizing recycling machine

Working Flow of HDPE PP waste plastic flakes pelletizing recycling machine:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

Photos of HDPE PP waste plastic flakes pelletizing recycling machine

Mian extruder machine of HDPE PP waste plastic flakes pelletizing recycling machine

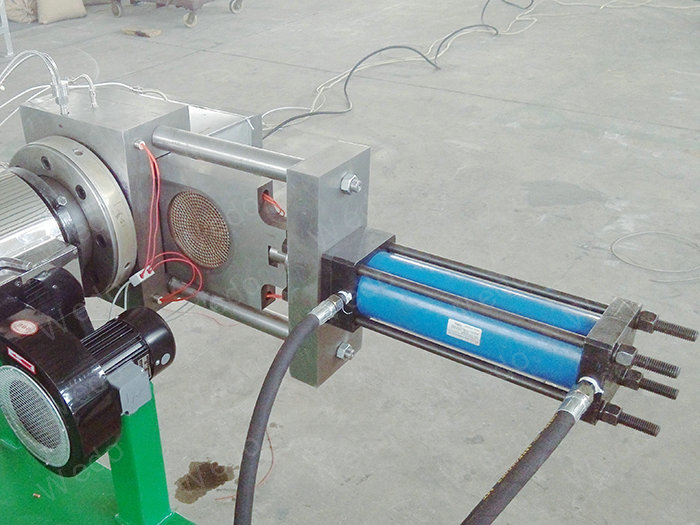

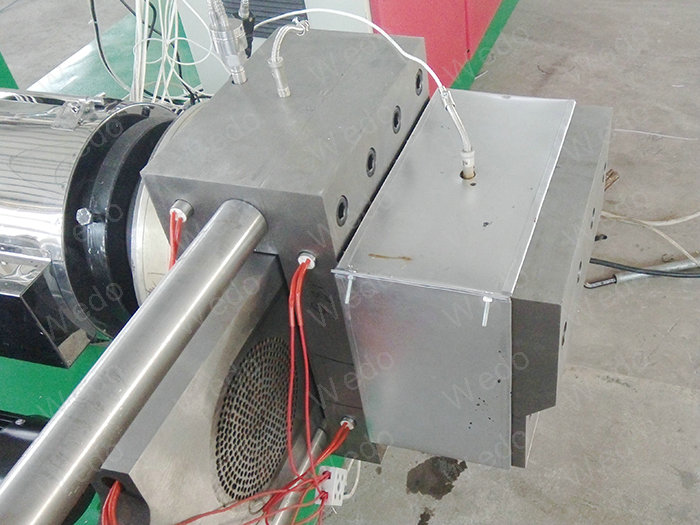

No-stop hydraulic sceen changer of HDPE PP waste plastic flakes pelletizing recycling machine

Second extruder, baby extruder of HDPE PP waste plastic flakes pelletizing recycling machine

hydraulic station of HDPE PP waste plastic flakes pelletizing recycling machine

Die head of HDPE PP waste plastic flakes pelletizing recycling machine

Pelletizer cutter of HDPE PP waste plastic flakes pelletizing recycling machine

Final pellets get from HDPE PP waste plastic flakes pelletizing recycling machine

The main parts function in HDPE PP waste plastic flakes pelletizing recycling machine(canbe customizable)

- スクリューフィーダー: ペレット化リサイクル機の最初のステップ, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, ホッパー内の材料を検出するネジ接続センサー, フレークがホッパーでいっぱいになったら, ネジが止まります; そして一度空に, スクリューフィーダーが作動し始めます.

- 押出機: 可塑化とデガッシング, 事前に圧縮された材料を溶かすために適用される特殊な単軸押出機. プラスチックのくずはよく溶けます, 第一段階の押出機で可塑化, プラスチックは第2段階の押出機によって押し出されます. ダブルゾーン真空デガッシングシステム付き, 低分子や水分などの揮発性物質が効率的に除去されます, 厚手の印刷フィルムや水分を含む素材に特に適しています.

- ノンストップ油圧スクリーンフィルターチェンジャー: 二段フィルタリング, 最初の押出機でのフォアフィルタリング, 2番目の押出機での微ろ過, ふるい交換の頻度を減らすため. フィルター技術の要件は、投入材料の品質と顆粒の計画された使用に大きく依存します.

- Water cooling: で出来ている 304 ステンレス鋼, 4 meters length that fill with water, too cooling the melted plastic.

- ペレット化の切断: supplied with speed steel and hard alloy steel cutting blades for reliable performance. コンパクトな構造でメンテナンスが少ない.

Parameters of HDPE PP waste plastic flakes pelletizing recycling machine:

| 容量 (kg / h) |

消費電力 (kw) |

水の消費量 | 労働 | 湿度コンテンツ |

| 100-150 | 150 | 水を冷たく保つ | 1-2 | <2% |

| 250-300 | 200 | 水を冷たく保つ | 1-2 | <2% |

| 350-400 | 280 | 水を冷たく保つ | 1-2 | <2% |

| 450-500 | 360 | 水を冷たく保つ | 1-2 | <2% |

Advantage of HDPE PP waste plastic flakes pelletizing recycling machine:

非常に低い労働要求.

安定した走行.

自動恒温制御.

CE認証, ISO9001認証, SGS認証

クライアントの要件と資料に基づく構成, 合理的な提案をする.