HDPE PP afval plastic vlokken pelletiseren recycling machine

Beschrijving:

HDPE PP waste plastic flakes pelletizing recycling machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, enzovoort.

After the processing of feeding, heating, melt, cooling, drogen, cutting etc., the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, afvoerbuizen, plastic sheet etc.

vidoe of HDPE PP waste plastic flakes pelletizing recycling machine

Working Flow of HDPE PP waste plastic flakes pelletizing recycling machine:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

Photos of HDPE PP waste plastic flakes pelletizing recycling machine

Mian extruder machine of HDPE PP waste plastic flakes pelletizing recycling machine

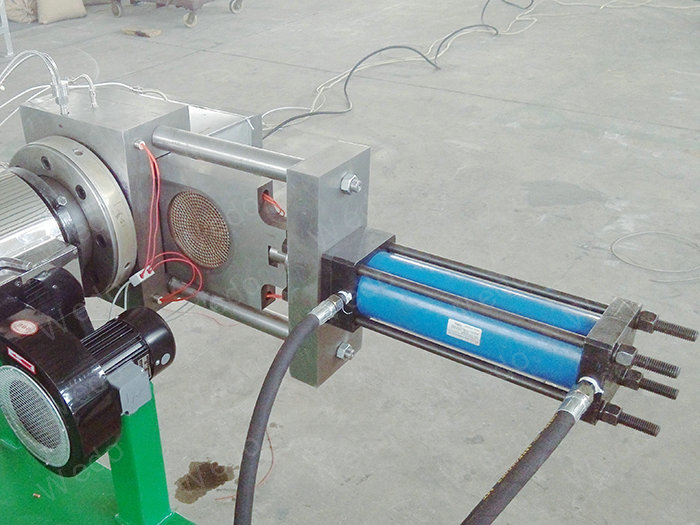

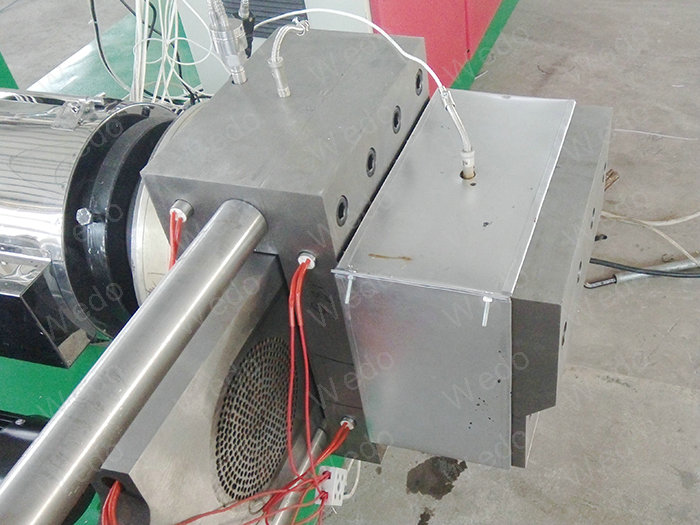

No-stop hydraulic sceen changer of HDPE PP waste plastic flakes pelletizing recycling machine

Second extruder, baby extruder of HDPE PP waste plastic flakes pelletizing recycling machine

hydraulic station of HDPE PP waste plastic flakes pelletizing recycling machine

Die head of HDPE PP waste plastic flakes pelletizing recycling machine

Pelletizer cutter of HDPE PP waste plastic flakes pelletizing recycling machine

Final pellets get from HDPE PP waste plastic flakes pelletizing recycling machine

The main parts function in HDPE PP waste plastic flakes pelletizing recycling machine(canbe customizable)

- Screw feeder: the first step of the pelletizing recycling machine, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

- Extruder: tot plastificering en ontgassing, een gespecialiseerde enkelschroefsextruder die wordt toegepast om het voorverdichte materiaal te smelten. De plastic restjes zullen goed gesmolten zijn, geplastificeerd in de eerste fase extruder, en het plastic zal worden geëxtrudeerd door de extruder van de tweede fase. Met dubbelzone-vacuümontgassingssysteem, vluchtige stoffen zoals laagmoleculaire stoffen en vocht worden efficiënt verwijderd, vooral geschikt voor zwaar bedrukte film en materiaal met enig watergehalte.

- Non-stop hydraulische zeeffilterwisselaar: dubbeltraps filtering, vóór het filteren in de eerste extruder, en fijnfilteren in de tweede extruder, om de frequentie van het vervangen van filterzeven te verminderen. De eisen aan de filtertechnologie zijn sterk afhankelijk van de kwaliteit van het invoermateriaal en het geplande gebruik van granulaten.

- Water cooling: made of 304 roestvrij staal, 4 meters length that fill with water, too cooling the melted plastic.

- Snijden pelletiseren: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Parameters of HDPE PP waste plastic flakes pelletizing recycling machine:

| CAPACITEIT (kg/u) |

ENERGIEVERBRUIK (kw) |

WATERVERBRUIK | WERK | VOCHTIGHEIDSGEHALTE |

| 100-150 | 150 | Houd water koel | 1-2 | <2% |

| 250-300 | 200 | Houd water koel | 1-2 | <2% |

| 350-400 | 280 | Houd water koel | 1-2 | <2% |

| 450-500 | 360 | Houd water koel | 1-2 | <2% |

Advantage of HDPE PP waste plastic flakes pelletizing recycling machine:

Zeer laag arbeidsverzoek.

Stabiel lopen.

Automatische constante temperatuurregeling.

CE-certificering, ISO9001-certificering, SGS-certificering

Configuratie op basis van klantbehoefte en materiaal, en geef een redelijk voorstel.